How Manufacturing Flaws Can Lead to Product Liability Lawsuits

Consumers expect the products they use to be safe, whether it's a mobile phone or a motor vehicle. Sadly, safety is not always guaranteed. Even if a person is using a product as directed, there is a change that a defect in this product can cause injury through no fault of the consumer. That's when a Scranton product liability lawyer can be helpful.

Consumers expect the products they use to be safe, whether it's a mobile phone or a motor vehicle. Sadly, safety is not always guaranteed. Even if a person is using a product as directed, there is a change that a defect in this product can cause injury through no fault of the consumer. That's when a Scranton product liability lawyer can be helpful.

There are many reasons why a product may be dangerous. We'd like to consider the role of manufacturing problems in product liability lawsuits below.

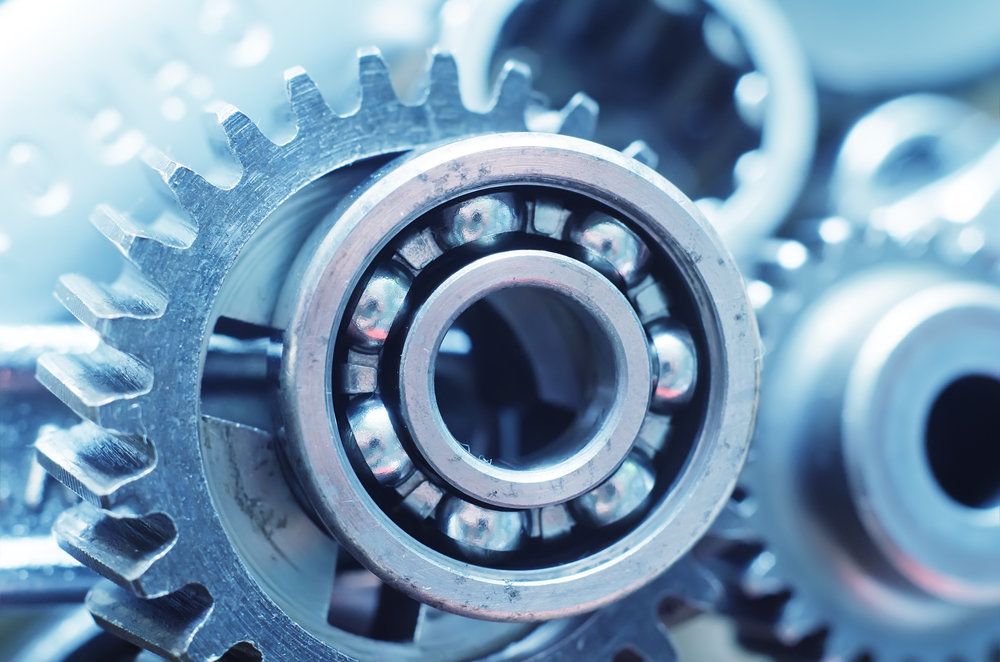

Product Manufacturing Flaws Explained

A product manufacturing flaw is just what it sounds like. These are issues with a product that arise during the actual assembly or manufacturing process. The product is otherwise safe for regular use, but these issues with manufacturing lead to a host of dangers that can can cause catastrophic and even fatal injuries to consumers.

Examples of Manufacturing Flaws

There are many different kinds of manufacturing flaws. Below are just a few examples to consider.

-

Problems with Materials – If the wrong kind of plastic, metal, or wood is used to make a product, there's a change that it may break or malfunction in some way that could be harmful.

-

Problems with Parts and Components – The wrong pieces or parts may be used to make a product, increasing the likelihood of serious injuries.

-

Contamination During Assembly – When foreign objects or substances wind up in an item or in item components, the product may wind up being less safe as a result. This is why cleanliness matters when making a product.

-

Issues with Manufacturing Quality – Mistakes can happen, whether it's people manufacturing a product or machines on an assembly line. Unfortunately, these mistakes can lead to major injuries.

-

Lack of Quality Control and Testing – Testing and quality control should be a given when it comes to products on the market. A lack of testing and quality control may mean defective products wind up on the market.

Manufacturing Flaws vs. Design Flaws

It's important that we make a finer distinction between types of product defects, namely how manufacturing flaws differ from design flaws. While manufacturing flaws arise when a product is being made, design flaws refer to inherent dangers in a product.

When a design flaw is present, it does not matter if the product is made properly; this product is dangerous in and of itself because of its design. In general design flaws are more common than manufacturing flaws.

Can Manufacturing Flaws Be Prevented?

Yes.

Companies can be diligent and make sure that the right material and components are used when crafting their products. Trained workers can be hired to make these items or monitor the quality of the items that are created. Some kind of quality testing ought to be in place as well to ensure that the finished products are safe and free from manufacturing issues that could pose a danger to consumers.

How a Product Liability Lawyer Can Help

Product liability lawsuits can bring industry-wide change, making things safer for consumers on a day-to-day basis. These cases can be complicated, however, and many companies have legal teams in place to combat litigation of this kind. By working with a skilled product liability lawyer, you will not need to feel intimidated. Your attorney will work diligently to hold the negligent company accountable and protect consumers from harm.

Contact Foley Law Firm

If you would like more information about your legal rights and options in cases that involve defective products, be sure to contact an experienced product liability lawyer today. We will discuss the nature of your case and develop and legal strategy that hole companies accountable.